Salford

Salford 5200 ENFORCER

-

ID # 32595381

- Back ID:32595381

- Book a Demo

- Get Directions

| Part of Salford’s signature Independent Series lineup, the 5200 Enforcer takes high-speed tillage to the next level. Built to perform in even the toughest field conditions, the Enforcer designed to meet your tillage needs – leveling and uniformly mixing soil and residue between 3” and 5” at speeds of up to 9 mph. The go-to machine for high-speed primary tillage, the redesigned blade layout of the 5200 increases the stability of the machine, providing ideal residue blending and superior field finishing. The machine’s heavy-duty blade mounts and added clearance on the 5200 penetrate dry, hard ground and won’t plug in wet soil. |

|

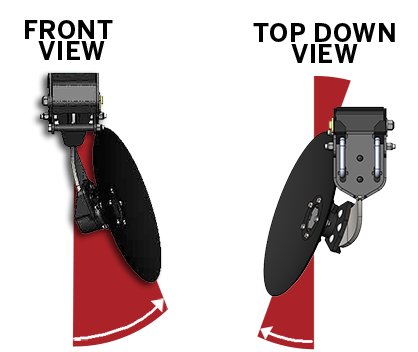

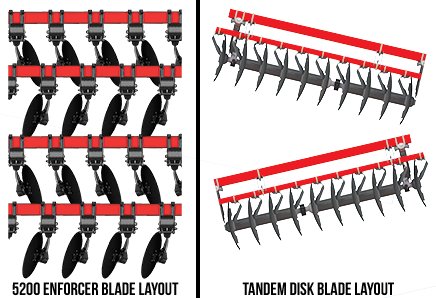

The 5200 has four rows of blades compared to a traditional tandem disk only having two rows. The result is twice as much work in one pass. The 5200 also has independently mounted blades with rubber compression obstacle protection. This allows each blade to flex up to 5 inches vertically over obstacles in the field. With no gang bolt, spools or scrapes the 5200 can move through much more residue and moisture than a tandem disk, with far less risk of plugging. When maintaining the 5200 there is no need to replace spools or scrapers and each blade and bearing can be serviced individually. |

|

The 5200 Enforcer starts with an innovative blade mount. The arm of the blade mount is made of a heavy spring steel, bent in multiple directions. |

|

5200 Enforcer models are available with either manually adjustable, or FLEX FINISH hydraulically adjustable finishing systems. Three rows of 1/2 inch diameter by 20 inch high leveling tines help to evenly distribute soil and residue to eliminate clumps and bunches of material on the surface. The 14 inch diameter rolling basket crushing soil clods and residue leaving a smooth surface for other field operations such as seeding, spraying and harvesting. The rolling basket also helps pin residue to the surface, helping to minimize drifting material. FLEX FINISH hydraulically adjustable finishing systems allow operators to adapt to field conditions on the fly by adjusting the rolling basket pressure, tine pitch, or both right from the tractor cab. |

|

Series |

Salford Tillage | Salford Tillage | Salford Tillage | Salford Tillage | Salford Tillage | Salford Tillage | Salford Tillage | Salford Tillage |

|

Product Type |

5200 Enforcer | 5200 Enforcer | 5200 Enforcer | 5200 Enforcer | 5200 Enforcer | 5200 Enforcer | 5200 Enforcer | 5200 Enforcer |

|

Model |

5200 | 5200 | 5200 | 5200 | 5200 | 5200 | 5200 | 5200 |

|

Size |

12 ft | 16 ft | 19 ft | 22 ft | 25 ft | 29 ft | 36 ft | 39 ft |

|

Folding (Multi-Section) or Non-Folding |

Non Folding | Folding | Folding (Multi-Section) | Folding (Multi-Section) | Folding (Multi-Section) | Folding (Multi-Section) | Folding (Multi-Section) | Folding (Multi-Section) |

|

Fold Type |

N/A | 3 Piece Flat Fold | Single-Fold Wing | Single-Fold Wing | Single-Fold Wing | Single-Fold Wing | Single-Fold Wing | Single-Fold Wing |

|

Working width, ft (m) |

12 ft 1 in | 15 ft 5 in | 18 ft 9 in | 22 ft 1 in | 25 ft 5 in | 28 ft 9 in | 35 ft 5 in | 38 ft 9 in |

|

Transport width, ft (m) |

13 ft 10 in | 11 ft 6 in | 15 ft 2 in | 15 ft 2 in | 15 ft 2 in | 15 ft 2 in | 20 ft 6 in | 20 ft 6 in |

|

Transport height, ft (m) |

N/A | 9 ft | 10 ft 3 in | 12 ft 4 in | 13 ft 5 in | 14 ft 7 in | 14 ft 6 in | 15 ft 11 in |

|

Approximate weight, lb (kg) (w/ Standard harrows unless stated otherwise) |

13500 lbs | 15600 lbs | 23200 lbs | 23750 lbs | 25900 lbs | 30100 lbs | 37200 lbs | 38000 lbs |

|

Other sizes available, number of widths |

- | - | - | - | - | - | - | - |

|

Front row(s) ground engaging equipment (description) |

Concave Blade | Concave Blade | Concave Blade | Concave Blade | Concave Blade | Concave Blade | Concave Blade | Concave Blade |

|

Front row(s) ground engaging equipment (quantity) |

2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

|

Front row(s) equipment quantity |

28 | 36 | 44 | 52 | 60 | 68 | 84 | 92 |

|

Front row(s) equipment mount |

Rubber V-Wedge Suspension w/ V-Bolt Mount | Rubber V-Wedge Suspension w/ V-Bolt Mount | Rubber V-Wedge Suspension w/ V-Bolt Mount | Rubber V-Wedge Suspension w/ V-Bolt Mount | Rubber V-Wedge Suspension w/ V-Bolt Mount | Rubber V-Wedge Suspension w/ V-Bolt Mount | Rubber V-Wedge Suspension w/ V-Bolt Mount | Rubber V-Wedge Suspension w/ V-Bolt Mount |

|

Equipment spacing, in (mm) |

5 in | 5 in | 5 in | 5 in | 5 in | 5 in | 5 in | 5 in |

|

Equipment size, in (mm) |

22 in or 24 in | 22 in or 24 in | 22 in or 24 in | 22 in or 24 in | 22 in or 24 in | 22 in or 24 in | 22 in or 24 in | 22 in or 24 in |

|

Angle |

5 Bolt Double Tapered Roller Bearing | 5 Bolt Double Tapered Roller Bearing | 5 Bolt Double Tapered Roller Bearing | 5 Bolt Double Tapered Roller Bearing | 5 Bolt Double Tapered Roller Bearing | 5 Bolt Double Tapered Roller Bearing | 5 Bolt Double Tapered Roller Bearing | 5 Bolt Double Tapered Roller Bearing |

|

Bearings |

Multi-lip sealed, maintenance free rebuildable hubs | Multi-lip sealed, maintenance free rebuildable hubs | Multi-lip sealed, maintenance free rebuildable hubs | Multi-lip sealed, maintenance free rebuildable hubs | Multi-lip sealed, maintenance free rebuildable hubs | - | - | - |

|

Rear row(s) ground engaging equipment (description) |

Notched Low Concavity Blades | Notched Low Concavity Blades | Notched Low Concavity Blades | Notched Low Concavity Blades | Notched Low Concavity Blades |

|

Rear row(s) ground engaging equipment (quantity) |

- | - | - | - | - |

|

Rear row(s) equipment quantity |

24 | 30 | 36 | 42 | 48 |

|

Rear row(s) equipment mount |

4pc rubber torsion suspension | 4pc rubber torsion suspension | 4pc rubber torsion suspension | 4pc rubber torsion suspension | 4pc rubber torsion suspension |

|

Equipment spacing, in (mm) |

10 in | 10 in | 10 in | 10 in | 10 in |

|

Equipment size, in (mm) |

22 in | 22 in | 22 in | 22 in | 22 in |

|

Angle |

17° open angle and 4° tipped under angle | 17° open angle and 4° tipped under angle | 17° open angle and 4° tipped under angle | 17° open angle and 4° tipped under angle | 17° open angle and 4° tipped under angle |

|

Bearings |

Multi-lip sealed, maintenance free rebuildable hubs | Multi-lip sealed, maintenance free rebuildable hubs | Multi-lip sealed, maintenance free rebuildable hubs | Multi-lip sealed, maintenance free rebuildable hubs | Multi-lip sealed, maintenance free rebuildable hubs |

|

Equipment options |

- | - | - | - | - |

|

Transport wheel mounting |

8-bolt | 8-bolt | 8-bolt | 8-bolt | 8-bolt | 8-bolt | 10-bolt | 10-bolt |

|

Transport tires |

305/70 R22.5 Recapped Truck Tires | 305/70 R22.5 Recapped Truck Tires | 305/70 R22.5 Recapped Truck Tires | 305/70 R22.5 Recapped Truck Tires | 305/70 R22.5 Recapped Truck Tires | 305/70 R22.5 Recapped Truck Tires | 425/65 R22.5 Recapped Truck Tires | 425/65 R22.5 Recapped Truck Tires |

|

Wing wheel mounting |

N/A | N/A | 6-bolt | 6-bolt | 6-bolt | 8-bolt8-bolt | 8-bolt | - |

|

Wing tires |

N/A | N/A | 245/70 R19.5 Recapped Truck Tires | 245/70 R19.5 Recapped Truck Tires | 245/70 R19.5 Recapped Truck Tires | 305/70 R22.5 Recapped Truck Tires | 305/70 R22.5 Recapped Truck Tires | 305/70 R22.5 Recapped Truck Tires |

|

Gauge wheel mounting |

N/A | N/A | Single Fixed Gauge Wheels per Wing | Single Fixed Gauge Wheels per Wing | Single Fixed Gauge Wheels per Wing | Single Fixed Gauge Wheels per Wing | Single Fixed Gauge Wheels per Wing | Single Fixed Gauge Wheels per Wing |

|

Guage wheel tires |

N/A | N/A | 245/70 R19.5 Recapped Truck Tires | 245/70 R19.5 Recapped Truck Tires | 245/70 R19.5 Recapped Truck Tires | 245/70 R19.5 Recapped Truck Tires | 245/70 R19.5 Recapped Truck Tires | 245/70 R19.5 Recapped Truck Tires |

|

Hookup to tractor, mounted or pull-type |

Category 3 or Category 4 Hitch | Category 3 or Category 4 Hitch | Category 3 or Category 4 Hitch | Category 3 or Category 4 Hitch | Category 3 or Category 4 Hitch | Category 3 or Category 4 Hitch | Category 3 or Category 4 Hitch | Category 3 or Category 4 Hitch | Category 3 or Category 4 Hitch | Category 3 or Category 4 Hitch | Category 3 or Category 4 Hitch |

|

Typical operating depth, in (mm) |

3-5 in | 3-5 in | 3-5 in | 3-5 in | 3-5 in | 3-5 in | 3-5 in | 3-5 in |

|

Operating speed (mph) |

5.5-9 mph | 5.5-9 mph | 5.5-9 mph | 5.5-9 mph | 5.5-9 mph | 5.5-9 mph | 5.5-9 mph | 5.5-9 mph |

|

Depth control |

Single point depth control | Single point depth control | Single point depth control | Single point depth control | Single point depth control | Single point depth control | Single point depth control | Single point depth control |

|

Fore/aft leveling |

- | - | - | - | - | - | - | - |

|

Required power, hp/ft (kw/m) |

15-20 hp/ft | 15-20 hp/ft | 15-20 hp/ft | 15-20 hp/ft | 15-20 hp/ft | 15-20 hp/ft | 15-20 hp/ft | 15-20 hp/ft |

|

Remote Hydraulic Values required |

3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

|

Hydraulic Pressure |

- | - | - | - | - | - | - | - |

| Name | Link |

| 5200 Enforcer Literature | Download |

MORE CLEARANCE AND MORE WORK IN ONE PASS

MORE CLEARANCE AND MORE WORK IN ONE PASS